Sustainable Packaging Management

Key Performance in 2024

Reduce Virgin plastic from packaging research and development projects

Reduce GHG emissions from plastic usage reduction, totalling

Plastic packaging from recycled material

Take back plastic for recycling

Reduce the use of single-use plastics

Recycled Post-consumer Packaging

Key Progress in 2024

Plastic packaging collection programs for recycling as follows:

* Waste Sorting Bin Project

* Recycling Station project

Post-consumer packaging reuse programs, as follows:

* 7-Eleven Carry Bag project: plastic made from pallet wrap at distribution centers

* Employee Uniform project: uniforms made from recycled plastic bottles

* 7-Eleven Shopping Basket project: shopping baskets made from break case crates

* Eco-Friendly Multipurpose Yard project: for orphan plastic waste

* Eco-friendly-Empty Bottles Are Not Wasted project

Supporting the SDGs

SDG 8 Promote sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all

8.4 Improve progressively global resource efficiency in consumption and production and endeavour to decouple economic growth from environmental degradation

SDG 12 Ensure sustainable consumption and production patterns

12.2 Achieve the sustainable management and efficient use of natural resources

12.5 Substantially reduce waste generation through prevention, reduction, recycling and reuse

Performance Against Goal

Results of the “Double Materiality Matrix”

Sustainability Dimensions

Impact level for application in business operations

Progress against Short-term and Long-Term Goals

Private Brand utilizing plastic packaging must be reusable, recyclable, or compostable

Performance Summary 2024

Reduction of virgin plastic

Packaging development project

Reduction of single-use plastics usage project

Recycled material usage project

Remark: % Coverage 100

Post-Consumer packaging recycled project

Take back used packaging from consumers

Choose environmentally friendly plastic packaging

Plastic water bottles

Other plastic

Cardboard box

* Guidelines or methods of collecting data is available at “Recycling Station” project page 77, “Love the Earth – Empty Bottles Are Not Wasted" project page 79 and “Waste Separation Bins” project page 77

Reusable packaging

Choose environmentally friendly plastic packaging

Recyclable packaging

Remark: % Coverage 100

Compostable packaging

Remark: % Coverage 100

Total plastic packaging consumption

Average plastic packaging consumption per store

Remark: % Coverage 100

Share of total plastic consumption classified by type

Total non-plastic packaging usage

| Material type | Coverage (% of cost of goods sold) | Weight of packaging Consumption | Recycled or certified Material packaging | Target 2024 |

|---|---|---|---|---|

Wood or Paper Wood or Paper |

||||

Metal (Steel, Aluminum) Metal (Steel, Aluminum) |

||||

Glass Glass |

Risks and Opportunities

The amount of plastic packaging waste from consumer goods has increased significantly and is recognized as an environmental issue requiring urgent management and control. Due to plastic's chemical properties-being durable, strong, easy to produce and form shape, low-cost, and convenient for distribution and transportation-it has become widely used. However, these same properties cause plastic to take a long time to decompose naturally, during which harmful substances like plasticizers and other toxic chemical components are released into the environment. This has prompted the need for immediate action to address plastic packaging waste. Sustainable packaging has thus become a key concern for consumers when making purchasing decisions, creating challenges for the manufacturing, retail, food, and beverage industries to adapt and meet the expectations of consumers, the public sector, and civil society. The Company supports and develops sustainable packaging, innovations, and alternative packaging solutions-since the processes in design, production, and to effective supply chain management. These efforts align with the Extended Producer Responsibility (EPR) principles. The Company has announced a policy and set a target that 100% of its controlled packaging must be reusable, recyclable, or biodegradable. A Take-Back System is being implemented for used packaging, enabling recycling or reuse processes. The Company is also collaborating with suppliers to improve recycling systems and has established a working group on sustainable packaging management to monitor changes in relevant regulations that could affect operating costs, such as waste management fees to a central organization. To minimize reputational risks, the Company remains committed to responsible practices throughout the supply chain, focusing on environmentally friendly and consumer-safe packaging materials while considering other factors that may impact the environment. Examples include challenges such as highly recyclable but heavy packaging, which increases greenhouse gas emissions during transportation; lightweight packaging that reduces resource use and costs but complicates recycling processes; and eco-friendly packaging that lacks practical functionality.

Therefore, effective innovation and plastic packaging management are crucial drivers for enhancing distribution capabilities. This approach ensures that the Company's products meet consumer needs while delivering safe packaging that maintains product quality. The packaging must not negatively impact the health and safety of customers who come into direct contact with packaging, nor affect employees involved in production and transportation processes, all while solving environmental issues sustainably.

Management Approach

The Company prioritizes the development of technology and innovation for comprehensive packaging management, from production to delivery to consumers. CP ALL aims to become a leading organization by implementing a sustainable packaging policy and selecting environmentally friendly packaging for its private brand products. The Company’s approach encompasses all aspects, from packaging design and selection (Re-design), the reuse of used packaging (Reusable Packaging), recyclable packaging (Recyclable Packaging), the use of alternative materials that are naturally biodegradable (Compostable Material Packaging), and the use of packaging made from recycled materials (Recycled Material Packaging). The Company also ensures the use of packaging materials certified by credible organizations. Additionally, the Company monitors related laws, regulations, and requirements for packaging waste management, such as prohibiting the use of certain packaging types for wrapping and transporting products to ensure compliance with legal standards.

The Company extends the environmental responsibility to post-consumption product management, following the Extended Producer Responsibility (EPR) principles. The Company also places importance on data collection, data analysis, and operational audits to establish a database for policy review and future planning. This ensures that the Company's packaging management processes are efficient, reduce packaging waste, minimize environmental impacts and stakeholder concerns, and meet the demands of green markets both domestically and internationally.

Circular Economy

The Company manages packaging waste based on the Circular Economy concept, aiming to minimize the amount of plastic waste sent to landfills. Plastic packaging for the Company’s controlled products (Private Brand) is managed to ensure it can be reused (Reusable), recycled (Recycle), or naturally decomposed (Compostable). This is implemented through three main measures: “Reduce-Reuse-Recycle (3R)” as follows:

Reduce plastic usage

at-source

--------

The Company has implemented a "Sustainable Packaging" policy as a framework for sustainable packaging operations. This policy encompasses the

direction setting, strategy, planning, and promotion of research and development for environmentally friendly packaging innovations. This approach also includes studying and selecting new alternative packaging options that offer greater sustainability

Reduction and Substitution at the Consumption Stage

--------

The Company has initiated strategic projects to reduce the use of single-use plastics and launched campaigns to encourage customer, social, and community participation in reducing plastic waste

Management of Post-Consumption Packaging Waste

--------

The Company has launched strategic projects to bring used packaging back into reuse under the circular economy concept. This initiative involves collaboration with all relevant stakeholders and transparently discloses the volume and types of plastic used, reduction efforts, reuse, and recycling processes through the annual sustainability report

The Company systematically operates according to sustainable packaging management measures whereby operational performance is monitored and recorded regularly. The results and benefits received from the project implementation, inclusive of single-use plastic packaging reduction, packaging waste reduction by category, reduction in greenhouse gas emissions, etc., through various project implementation in 2024 are as follows:

1. Reusable Packaging Project

Durable bag

The Company collaborates with business partners to produce carry bags for use in 7-Eleven stores with a thickness of 36 microns. These bags are made from recycled plastic, offering durability and the ability to be reused multiple times, thereby reducing the need for single-use plastic bags. This initiative is part of the commitment to minimizing plastic waste and promoting reuse.

Impacts and Benefits

Reduced plastic waste

Reduced GHG emissions

Corrugated boxes used in the factory

CPRAM has implemented a project to efficiently reuse corrugated boxes in the production process. Used corrugated boxes are collected and sorted before being reused in the production process or as packaging for products again, helping reduce paper usage by 245 tonnes.

2. Programs to Promote the Use of Recyclable Packaging

Elimination of packaging materials posing recycling challenges for Lotus’s brand products project

Lotus’s has established a goal to eliminate difficult-to-recycle materials from all Lotus’s brand products by 2030 as a measure to assist in environmental impact reduction. In 2024, Lotus can reduce the use of packaging made from new plastic pellets by 47 tonnes, reduce the use of packaging made from paper by 24.01 tonnes. In addition, Lotus’s also recognizes the importance of supporting consumer behavior in waste sorting as a means to complete the ClosedLoop Packaging System and fulfill the package waste management scope. Other notable support measures include aims to raise recycling awareness and understanding among the communities while promoting recycling through packaging waste pick-up point expansion at various branches nationwide.

Ongoing project: “Green Coffee Shop” –Year 3

Coffee shops and bakery houses within the CP ALL Public Company Limited group continued to reduce solid waste including plastic cups and single-use plastic straws as jointly announced to the Ministry of Natural Resources and Environment. The company continuously cooperates with entrepreneurs to reduce plastic waste to encourage coffee shops to separate waste within their stores for recycling purposes or reuse. In addition to reducing waste quantities, the usage of creative packaging or environmentally friendly materials through various activities of the 3 brands are as follows:

ALL Cafe

----------

Kudsan Bakery & Coffee

----------

Bellinee's Bake & Brew

----------

3. Project to Reduce the Use of Single-Use Plastic Packaging

Ongoing project: “Reduce and Replace” single-use plastic”

The Company invites 7-Eleven store patrons to refuse to accept plastic spoons, forks, straws, glasses, and to carry their own cloth carry bags to reduce plastic packaging usage and continuously campaign for usage of alternative, environmentally friendly materials. In 2024, There are 3,745 million plastic reductions and single-use plastics: spoons, forks, tubes and glass 1,217 million pieces.

Impacts and Benefits

Reduced single used plastic usage

Reduced GHG emissions

Ongoing project: “Green Packaging” Year 4

7-Eleven stores campaign to refrain from handing out small bags except for hot items and switch to environmentally friendly packaging in a stores located on islands or near natural attractions, numbering over 1,200 stores.

Cancel or replace sticker usage

Chilled thai food

CPRAM develops laminate film innovation, sealing film material capable of being printed, to replace sticker usage totaling 24.24 tonnes

Steamed rice bowl

CP ALL develops steamed rice bowls with side prints to replace sticker usage, totaling 41.32 tonnes

Impacts and Benefits

Reduced virgin plastics usage

Reduced GHG emissions

Reduced amount of waste from sticker

Say Hi to Bio Say No to Foam Project

The company aims to stop selling single-use foam packaging, a process that began in 2019, and continues alongside seminars to provide knowledge and campaigns for restaurant operators and general consumers. Through collaboration with business partners, over 530 eco-friendly product options have been created at affordable prices, making the company one of Thailand's key hubs for biodegradable packaging, sparking the movement for sustainable packaging.

Impacts and Benefits

Sales of eco-friendly packaging

(increased 12.93% or 45.65 million baht)

Plastic waste generated from sales of products within Makro is recycled

(increase of 238%, or equivalent to 1,890 tonnes)

4. Project to Promote Packaging Solutions from Recycled Materials

Shopping bags used in 7-Eleven

----------

Containing 10-30% recycled materials

Garbage bags used in offices and distribution centers

----------

Containing 60-100% recycled materials

Water pallets in 7-Eleven stores

----------

100% recycled materials

Corrugated cardboard box in CPRAM

----------

Containing 90-100% recycled materials

Hot sandwich tray made from recycled plastic

----------

CP ALL has developed packaging using recycled plastic for hot sandwich trays. With 20% recycled content, the initiative reduced the use of virgin plastic by 0.88 grams per piece, totaling 4.69 tonnes

5. Project to Promote Packaging Recycling

The Company establishes cooperation with suppliers, public sectors, private sectors, and educational sectors to separate waste, collect plastic packaging for recycling (Take Back), and reuse (Recycled Post-consumer Packaging). through various project implementation in 2024 are as follows:

Ongoing project: “Recycling Station”

Lotus’s continues to campaign and support consumers in achieving maximum utility of available resources, introduce behaviors in separating waste to enable recycling processes, establish comprehensive waste management systems through taking advantage of different branches to increase community coverage. The various branches act as Recycling Stations and create channels for receiving raw materials and transferring to network partner systems for recycling or reuse.

Plastic bottle pick-up point

Recycled materials collection point (PET plastic bottles

Clean plastic

Cardboard box

Impacts and Benefits

Successfully collected packaging waste for recycling and upcycling

Recovered plastic over

Collected boxes and cardboard over

Ongoing project: “Waste Separation Bins”

CP ALL promotes waste separation to ensure plastic packaging waste enters the Circular Economy management system. “Waste Separation Bins” are placed in front of every 7-Eleven branch nationwide. In 2024, the Company partnered with Nestlé Thailand's water business unit to install 100 Drop Boxes at selected 7-Eleven branches under the “Crush On You: Twist & Drop, Show Love to the World” project, collecting over 15,068 PET plastic bottles for recycling.

Impacts and Benefits

Plastic waste separated for recycling and utilized in communities exceeds

Reduced GHG emissions

Ongoing project: “7-Eleven stores shopping baskets” from broken brake cases at distribution centers

The Company collects damaged brake case crates from distribution centers and processes them into 7-Eleven store shopping baskets for customers as a means to reduce business activity waste and enable more cost-effective resource usage.

Impacts and Benefits

Reduce the production of shopping baskets

Reduced waste volumes from brake cases

Reduced GHG emissions

Ongoing project: “Employee Shirts” made from plastic bottles

The Company recycles plastic bottles into uniform shirts for 7-Eleven store employees and polo shirts for employees in the distribution center and office.

1.5 liter recycled plastic bottles 4 bottles

----------

1 7-Eleven store employee shirt

1.5 liter recycled plastic bottles 8 bottles

----------

1 distribution center employee polo shirt

0.6 liter recycled plastic bottles 12 bottles

----------

1 office staff polo shirt

In 2024, the Company produced over 743,243 shirts for employees in a process which reduced over 3,311,580 plastic bottles required for processing.

Impacts and Benefits

Reduced plastic waste to landfill

Reduced GHG emissions

Enhancing the value of contaminated plastic waste management in factories

CPRAM Co., Ltd. processes contaminated plastic waste from the production process by sending it to external companies for conversion into Refuse Derived Fuel (RDF). RDF is a biofuel produced from waste with high calorific value, which is a valuable energy source for further utilization.

Impacts and Benefits

Amount of plastic waste utilized

Ongoing project: “Love the Earth – Empty Bottles Are Not Wasted”

Separating empty plastic bottles can create multi-dimensional benefits. CP Axtra Public Company Limited collects PET bottles to be recycled into various products. This effort helps reduce the use of natural resources, supports religion, creates jobs, and promotes public health.

| Activities in 2024 | Alliances | Impacts and Benefits |

|---|---|---|

| Encouraging employees to drop off PET bottles at collection points | Head Office and Makro Distribution Center |

|

| Collecting PET bottles from distribution centers and nearby temples | Ja Daeng Temple |

|

“Rak Koh 24-Hour Project” (Love the Island 24 Hours)

CP ALL collaborates with the CONNEXT ED Foundation school network under the supervision and the “Trash-Free Community” initiative, encompassing both public and private sectors, to expand the “Trash-Free Sprout” project. This project aims to add value to waste on the island, reduce waste by an average of 50%, and generate income for the island community through 3 main principles.

In 2024, the Company launched the pilot project “Green Living: Love the Island 24 Hours” on Koh Phangan in 3 municipalities: Koh Phangan Subdistrict Municipality, Phet Phangan Subdistrict Municipality, and Ban Tai Subdistrict Municipality. The initiative also extended to Koh Tao, Surat Thani Province. There are plans to expand the project to 11 islands across 8 provinces by 2030.

Impacts and Benefits

Reused plastic

Reduced GHG emissions

6. Allocation of R&D Resources to Sustainable Packaging and Alternative Solutions

Eco-Friendly Packaging Design, Research, and Development Project

The Company focuses on designing, researching, and developing eco-friendly packaging (Eco-Design) to reduce the use of virgin plastic from the initial design stage. This initiative follows the Circular Economy concept, particularly for Private Brand products, aiming to minimize plastic consumption from the source.

Reducing plastic thickness

CP ALL in collaboration with partners, designs packaging with optimized thickness to ensure functional efficiency and product protection while minimizing plastic usage.

Banana packaging

CP ALL reduced the plastic thickness from 30 microns to 25 microns, resulting in

a total plastic reduction of 35.33 tonnes

Frozen products 7-Fresh two-compartment Tray

CP ALL developed plastic resin and reduced the plastic thickness from 0.92 mm to 0.82 mm, leading to

a total plastic reduction of 32.18 tonnes

Im-khum salad tray

CP ALL reduced the plastic thickness from 0.5 mm to 0.4 mm, leading to

a total plastic reduction of 93.14 tonnes

Food place (New design)

CP ALL introduced a new rectangular design for the Food Place tray and lid, reducing thickness and plastic usage by 7.5 grams per piece, resulting in

a total plastic reduction of 61.14 tonnes

Stickers for frozen products

CP ALL reduced the sticker thickness for frozen products from 90 microns to 80 microns, leading to

a total plastic reduction of 5.40 tonnes

Banding Plastic

Redesign of banding plastic for sushi trays by modifying the banding placement, plastic usage was reduced by 0.215 grams per piece, resulting in

a total plastic reduction of 0.71 tonnes

Impacts and Benefits

Reduced virgin plastic consumption

Reduced GHG emissions

Collaboration with suppliers to modify packaging designs and production methods

Single- compartment tray (New design)

CP ALL replaced the plastic lid with a sticker by using a top seal film, resulting in

a total plastic reduction of 97.02 tonnes

Two-compartment tray (Top seal)

CP ALL introduced a new design, replacing the plastic lid with a sticker with a top seal film, resulting in

a total plastic reduction of 16.94 tonnes

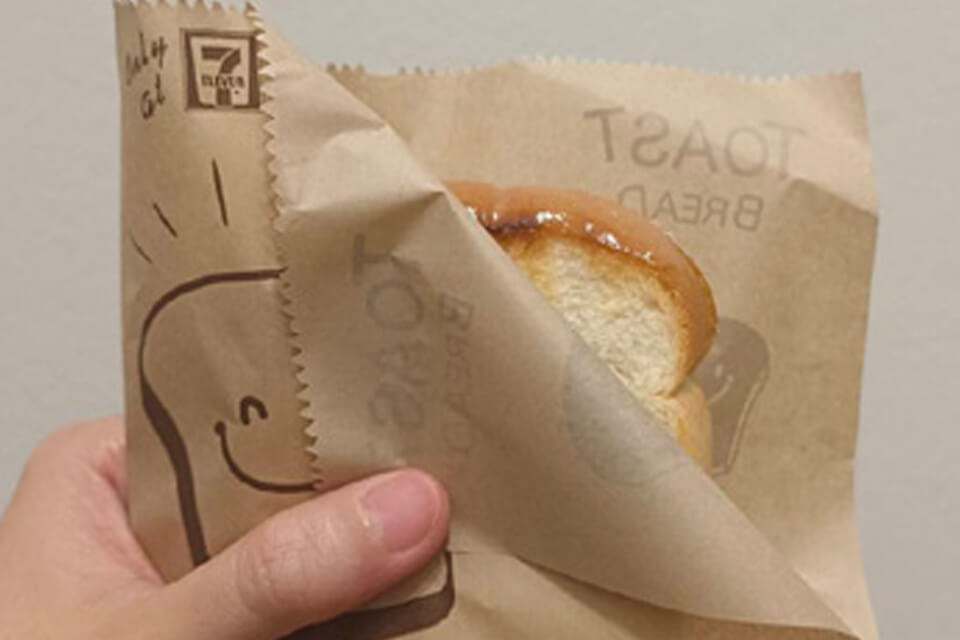

Toasted bread paper bag

CP ALL replaced PE-coated paper with grease-proof paper, resulting in

a total plastic reduction of 11.73 tonnes

21-Ounce food cup

CP ALL modified the plastic formulation used in packaging production, reducing plastic usage by 2.70 grams per piece, resulting in

a total plastic reduction of 27.26 tonnes

Cold dessert cup

CP ALL introduced a new design, reducing plastic usage by 0.70 grams per piece, resulting in

a total plastic reduction of 0.63 tonnes

22-Ounce ice cup

CP ALL changed the production process from Injection Molding to Thermoforming and switched the material from PP (Polypropylene) to PET (Polyethylene Terephthalate), reducing plastic usage by 7.50 grams per piece, resulting in

a total plastic reduction of 358.53 tonnes

Short spoon (New design)

CP ALL introduced a new design, reducing plastic usage by 0.28 grams per piece, resulting in

a total plastic reduction of 68.10 tonnes

Cold drink lid PP (New design)

CP ALL developed the new PP cold drink lid, replacing PET with PP to ensure the material matches the cup

(D4R concept). This change reduced usage by 4.00 grams per piece, resulting in

a total plastic reduction of 101.78 tonnes

Impacts and Benefits

Reduced virgin plastic consumption

Reduced GHG emissions

Compostable packaging

Eco-friendly cup

CP ALL has adopted Polybutylene Succinate (PBS)-coated paper for hot and cold beverages in 7-Eleven

stores located on islands, educational institutions, and office buildings, covering 1,200 branches. This initiative has resulted in

a total of 345.78 tonnes of material

Wooden chopsticks

CP ALL has opted for biodegradable wooden chopsticks, resulting in

a total of 14.64 tonnes of material

Wooden coffee stirrer

CP ALL has replaced plastic coffee stirrers with biodegradable wooden stirrers

a total of 2.04 tonnes

Biodegradable skewers

CP ALL has opted for biodegradable wooden skewers

a total of 361.91 tonnes

Impacts and Benefits

Biodegradable materials used

Selection of packaging materials from sustainably managed sources

Toasted bread paper bag

CP ALL uses greaseproof paper certified by the Program for the Endorsement of Forest Certification (PEFC)

Hot sandwich paper bag

CP ALL uses greaseproof paper certified by the Program for the Endorsement of Forest Certification (PEFC)

Paper straw wrapper

CP ALL uses FSC-certified paper from the Forest Stewardship Council (FSC)

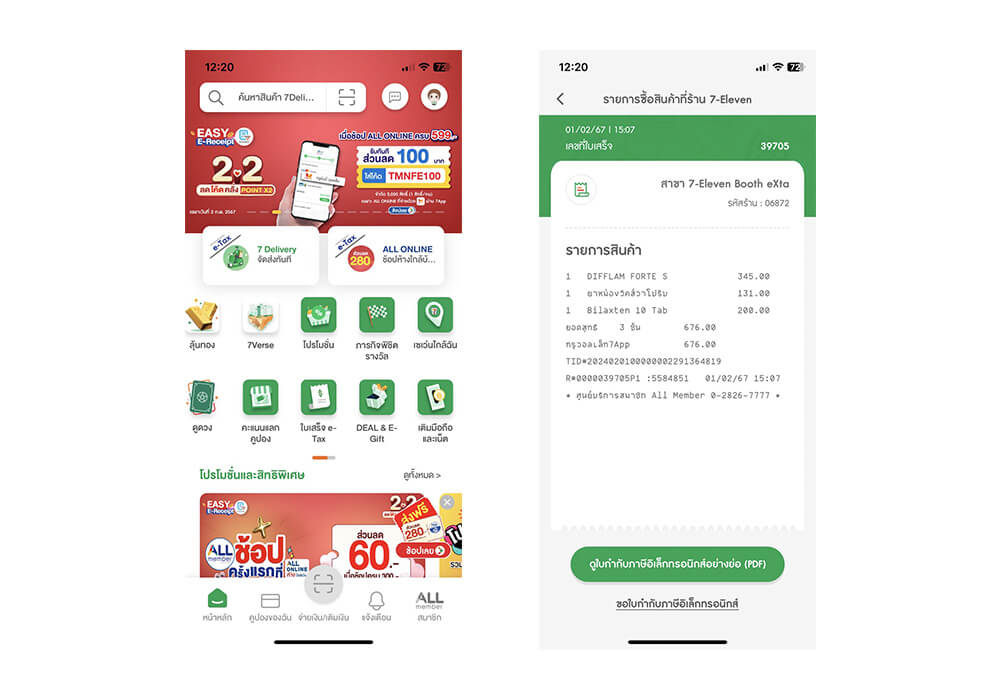

7-Eleven receipt paper

CP ALL selects paper sourced from sustainable forests, which has been verified and certified by the Forest Stewardship Council (FSC)

Sticker backing paper

CPRAM selects paper sourced from sustainable forests, which has been verified and certified by the Forest Stewardship Council (FSC)

Impacts and Benefits

Paper sourced from sustainably managed forests

Reduction in paper usage

Paper cups

CP ALL has reduced the paper grammage for cold beverage cups in the Non All Café product group, including Gulp drinks, Slurpee frozen beverages, and Jet Spray fountain drinks

Total reduction 171.04 tonnes

Sales receipts

CP ALL has transitioned from paper receipts to electronic slips

Hot sandwich packaging

CP ALL has transitioned from Artcard paper to Greaseproof paper, reducing paper usage

by 911.72 tonnes

Impacts and Benefits

Reduction in paper usage

Reduced GHG emissions

Examples of innovative packaging research & development project

CP ALL has developed a new cold beverage lid design, “PP cold-drink lid (new design),” to enhance drinking convenience without the need for a straw. This design ensures that both the lid and cup are made from the same PP (Polypropylene) material, aligning with the Design for Recycling (D4R) guidelines for recyclable plastic packaging. This project is divided into 4 phases, with the 3 phases currently in progress. Nationwide expansion is planned for 2025, focusing on 4 key aspects of development.

| Product quality | Customer acceptance | Environmental impact | Economic feasibilit |

|---|---|---|---|

| The new packaging must maintain the same characteristics and quality as the original | Both internal customers (operations team) and external consumers must accept the new design for use | The redesigned packaging must be recyclable | The new packaging should not affect the overall product cost, ensuring that the Company can continue to offer it at the same price while maintaining profitability. |

Packaging development details

The new cold beverage cup lid has been improved in both design and material, with the following key enhancements:

Impacts and Benefits

The product quality after delivery is better or equivalent to traditional packaging

Effectively protects the product from external contamination

Improved functionality allows for easier drinking without a straw

Research and development budget 19,900 Baht

Uses the same plastic material as the cup, enabling full recyclability in accordance with the D4R agreement

Recyclable PP plastic from cup lids amounts to approximately 1,440 tonnes per year

No impact on the overall product cost

Research and development project for PET trays for hot sandwich packaging

The Company has developed a new packaging format for hot sandwiches using recycled PET to reduce the use of virgin plastic, in line with the circular economy concept.This project is divided into 3 phases, and it is currently in Phase 3, where implementation has begun with plans for nationwide expansion. The development process encompasses 4 key aspects:

| Product quality | Customer acceptance | Environmental impact | Economic feasibilit |

|---|---|---|---|

| The new packaging must maintain the same characteristics and quality as the original | Both internal customers (operations team) and external consumers must accept the usage | The redesigned packaging must reduce the use of virgin plastic and replace it with recycled plastic that is safe for food contact | The new packaging should not affect the overall product cost, ensuring that the Company can continue to offer it at the same price while maintaining profitability. |

Packaging improvement details

The updated packaging utilizes 20% recycled PET (rPET) to reduce the use of virgin plastic. This approach minimizes environmental impact and enhances resource efficiency

Impacts and Benefits

The product quality after delivery is better or equivalent to using conventional packaging

Able to protect the product from external contamination

Research and development budget 10,000 Baht

Reduced use of virgin plastic by 124 tonnes per year

Recycled plastic used has been certified for food safety according to the specified standards

No impact on the overall product cost

Metric used to determine the compensation of executive members

The company cascaded the corporate KPIs to designated functions. A few KPIs are joint KPIs for the performances that required cross-functional collaboration. Executives, including Assistant Vice President of Purchasing division, Senior Manager of Packaging Development division - Food Support Center, and General Manager of Green Packaging Engagement and Partnership division, who are responsible for lowering amount (tons) of plastic used in products packaging. The actions require collaboration from suppliers to apply 3R concept to their production. To achieve this target, it reflects in their 10%, 25% and 30% weight in the respective executive’s performance evaluation (KPIs).

Related Policy and Guideline

| Packaging Policy | Download |