Sustainable Waste Management

Key Performance in 2023

Waste volume capable of reuse at of total waste quantity

63.83%Waste management from business operations (Alternative Purpose) from the total amount of waste

ร้อยละ 25.67% (16,260.86 tonnes)60 network communities and 2 offices participated in the

"Ton Kla Rai Tung"

project separated of waste sent it into the appropriate management process

32.49 tonnes

Key Progress in 2023

Integrated food product write-off reduction project (OA Ordering) reduced the amount of food excess or waste by

food to 520 communities

Surplus food donation to foundations project delivered

Adding value to production process by products project volume reduction loss of food in the production process

Ton Kla Rai Tung project continuous expansion to community networks, entrepreneurs

Significantly Affected Key Stakeholders

Supporting the SDGs

SDG 3 Ensure healthy lives and promote well-being for all at all ages

3.9 Substantially reduce the number of deaths and illnesses from hazardous chemicals and air, water and soil pollution and contamination

SDG 6 Ensure availability and sustainable management of water and sanitation for all

6.3 Improve water quality by reducing pollution, eliminating dumping and minimizing release of hazardous chemicals and materials

SDG 11 Make cities and human settlements inclusive, safe, resilient and sustainable

11.6 Reduce the adverse per capita environmental impact of cities, including by paying special attention to air quality and municipal and other waste management

SDG 12 Ensure sustainable consumption and production patterns

12.3 Halve per capita global food waste at the retail and consumer levels and reduce food losses along production and supply chains

12.4 Achieve the environmentally sound management of chemicals and all wastes throughout their life cycle, in accordance with agreed international frameworks, and

significantly reduce their release to air, water and soil in order to minimize their adverse impacts on human health and the environment

12.5 Substantially reduce waste generation through prevention, reduction, recycling and reuse

Performance Against Goal

2030 Goal

100%Reduce excess food or food scraps or the amount that needs to be eliminated and Reduce waste from the company's operations destined goes to landfill by

Progress against goals

Reduce excess food surplus or food waste or amount requiring disposal by the Company's operations destined goes to landfill by

Performance Summary 2023

Total amount waste

Remarks: Inclusive of hazardous waste and non-hazardous waste

Total waste per revenue

Remarks: Inclusive of hazardous waste and non-hazardous waste

Waste disposed and repurposed

Remarks: Inclusive of hazardous waste and non-hazardous waste

Waste disposed at landfills

Remarks: Inclusive of hazardous waste and non-hazardous waste

Waste Disposal Data Coverage

Remarks: Inclusive of hazardous waste and non-hazardous waste

Total Food loss and food waste

Remarks: Inclusive of hazardous waste and non-hazardous waste

Total food loss and food waste intensity per Unit of food sales

Total food loss and food waste classified by Business activities or Life cycle Stage

Proportion of food loss and food waste classified by Food category

Food waste disposed and repurposed

Food waste disposed and repurposed classified by Destination

| Project type | Project title |

|---|---|

Food loss, Food waste and waste Measurement Project Food loss, Food waste and waste Measurement Project |

|

Food loss, Food waste and Waste Reduce Project Food loss, Food waste and Waste Reduce Project |

|

Food loss, Food waste and Waste Recycling Project Food loss, Food waste and Waste Recycling Project |

|

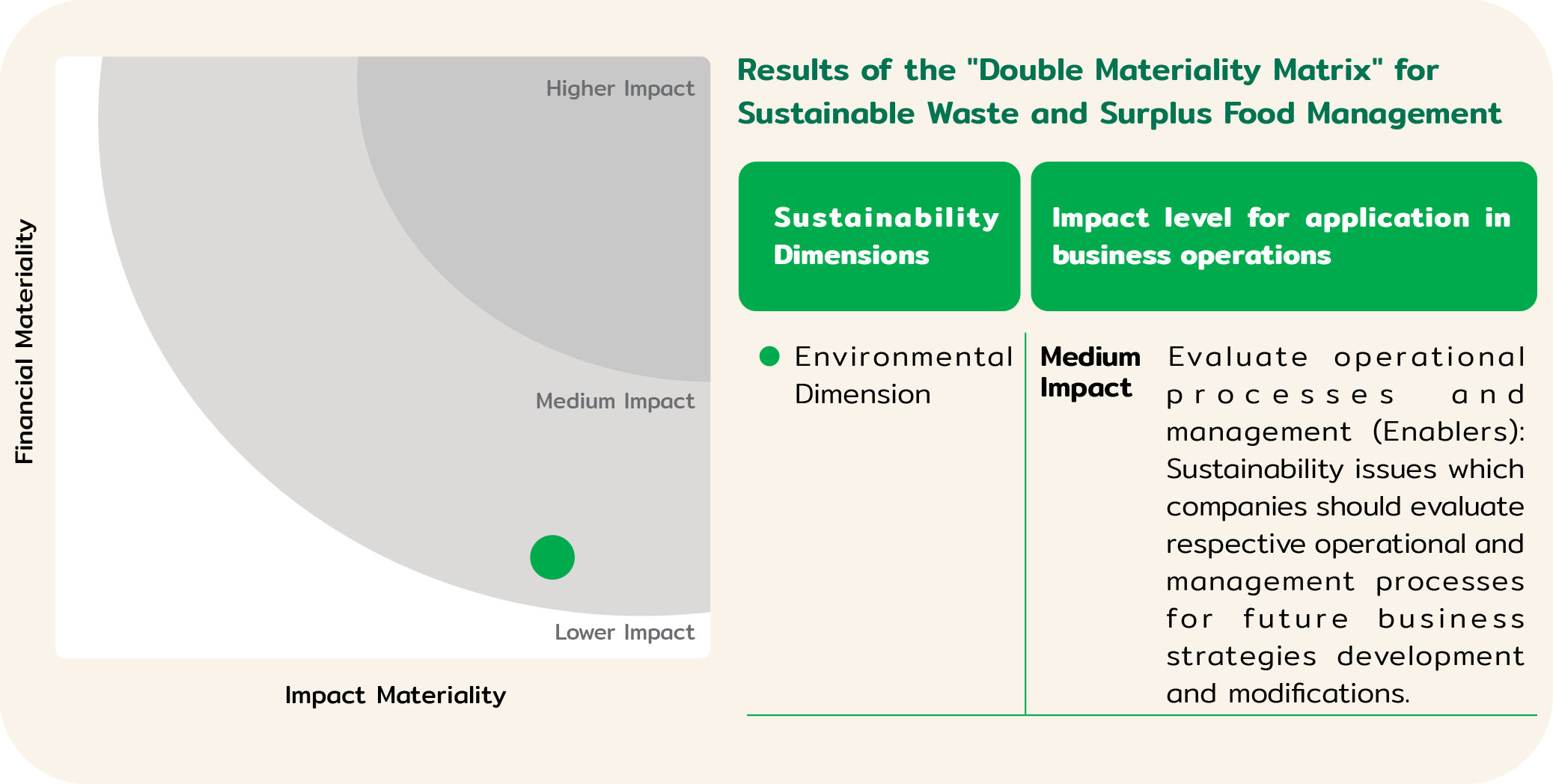

Risks and Opportunities

CP ALL Public Company Limited and its subsidiaries (“the Company”) emphasize sustainable waste and food waste management to reduce the risk of air pollution, water pollution, and soil pollution with potential to negatively impact nearby community health. With the Company food waste management policies aligned with the Zero Waste to Landfill by 2O3O approach to drive Goal 12 of the United Nations Sustainable Development Goals, joint initiatives with partners were conceived to manage food surplus, food loss, food waste, and miscellaneous wastes from business operations. As a means to reduce risks in overconsuming resources within the manufacturing process, the "1P3Rs" guidelines of the Food and Agriculture Organization comprising 1) Prevention, 2) Reduction, 3) Reuse, and 4) Recycling were adopted.

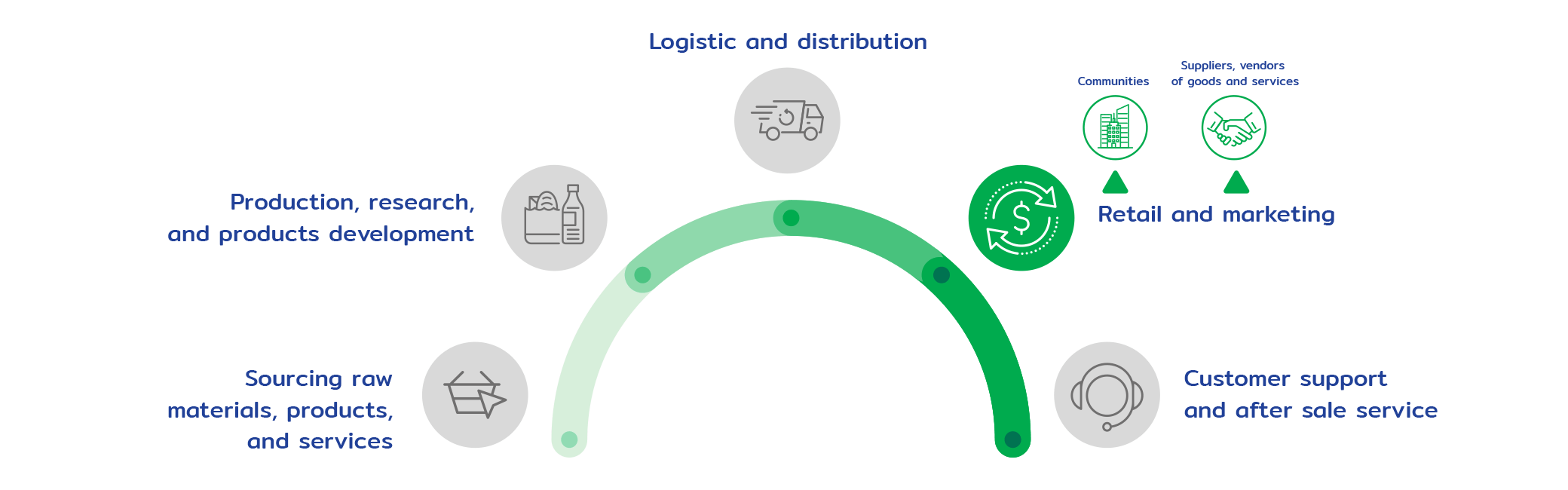

Comprehensive waste management methods employed by the Company consists of database creation for business activities, ranging from upstream to downstream processes, encompassing processing, manufacturing, logistics, distribution to consumer purchases. In analyzing waste and food waste data, inclusive of intra- and interorganizational resource consumption, wastes and food wastes are examined according to proportions, composition, and type. The results lead to decisive strategies and measures to reduce losses throughout the supply chain.

Management Approach

CP ALL Public Company Limited and its subsidiaries (“the Company”) realize the importance of sustainable waste and food waste management. The Company has established food loss and waste management policies with goals to reduce waste management through the Zero Waste to Landfill approach by 2030. In addition, the Company strives to drive the social sector through its operations and contribute to the United Nations Sustainable Development Goal 12 on Responsible Consumption and Production. The Company has implemented comprehensive waste management policies through establishing a food waste database which classifies waste by business activities from upstream to downstream operations from entire production process and product distribution channels until the product reaches the consumer. The mentioned system collects loss and food waste data through rigorous operations and accurate measurements thus permitting the Company to assess utilized resources and waste generation from both intra-organizational and inter-organizational processes. The system additionally enables analysis of proportion, composition and types of waste and food waste thus solidifies determination of appropriate strategies and measures to reduce losses throughout the supply chain.

In addition, the Company has continually cooperated with business suppliers to manage waste and food waste as a means to reduce air and water pollution risks potentially impacting the health of nearby communities. The Company has the capacity to manage all waste types comprising Food Surplus, Food Loss, Food Waste and other waste categories through applying the Food and Agriculture Organization guidelines and “1P3Rs” principles: 1) Prevention, 2) Reduction, Utilization, 3) Reuse, and 4) Recycling according to the circular economy concept. The stated approach reduces resource overutilization risks throughout the production process inclusive of reducing negative environmental impacts and waste management expenses.

Raw Material

Processing and Product

Distribution

Wholesale & Retail

Customer & Consumer

Food Loss reduction and Food Waste management

The Company adopted the Food and Agriculture Organization of the United Nations (FAO) and United Nations Environment Program (UNEP) food management guidelines to reduce food waste throughout various operations and has implemented the following relevant projects in 2O23

Prevention Measures for Food Waste and At-Source Waste Generation

Integrated Food Product Write-Off Reduction (OA: Ordering & Assortment) Project

The Company analyzes historical product sales data with focus on best-selling products and unsold products through the “GOT: Graphic Ordering Terminal” system to assist 7-Eleven store employees determine inventory, appropriate management, and amend product orders to reflect situational conditions including promotions and special events, etc. In 2O23, the Company achieved write-off waste reduction by 1.8O%, totaling 925 million Baht.

Production process waste reduction within the Zero Waste to Landfill project

CPRAM highlights increased production and equipment efficiency to assist in raw material and food loss reduction. In 2O23, measures to optimize the production process include more cost-effective materials usage, reduced raw material loss from trimming through ultrasonic cutting machines and precision tools to reduce processing inaccuracies, etc.

Reduction measures to increase benefits

The continuous project "Food to merit"

CP ALL and various foundations, delivers surplus food from 7-Eleven stores to communities, social organizations, charities, and those underserved. The Company carefully inspects the surplus food’s quality prior to delivery, such as the food condition and wholeness, freshness, food quality, FDA logo adherence, visible product expiration date, etc. The delivered food items to various foundations comprise bread, sandwiches, milk, vegetables, instant food, fruits, and cooked food. In 2O23, excess food deliveries from 7-Eleven stores, including 344 branches in the Bangkok metropolitan area, Prachuap Khiri Khan, Phuket, Chonburi Samut Prakan, Pathum Thani, Chiang Mai, Chiang Rai, Nonthaburi total over 511.84 tonnes and equate to 2,149,712 meals to 52O communities while reducing greenhouse gas emissions by 1,294.95 tCO2e.

The continuous project “Edible, Not Wasted”

corporation between Lotus’s and Scholars of Sustenance Foundation (SOS) to expand “Edible, Not Wasted” project through donating unsold food which retains consumption suitability and quality from Lotus’s Go Fresh, Chiang Mai Province and other private organization partners, totaling over 4O companies. The student recipients at Chiang Mai Rajabhat University dormitories, Mae Hong Son Campus, were provided over 2OO kilogram of raw materials per year for cooking to reduce living expense burdens. In Bangkok, over 35O Lotus’s Go Fresh branches deliver over 113 tonnes of unsold food which maintains quality and suitability for consumption to Bangkok Metropolitan Administration cleaning staff in 5O districts. Through sharing fullness, reducing expense burdens, reducing waste to landfill generation and waste separation at Lotus’s Go Fresh, officials can better manage waste and process wastes into fertilizers for public parks. This project is earmarked for expansion to Udon Thani and Khon Kaen provinces.

In addition, over 25,OOO pomelos unable to meet Lotus’s sweetness standards were donated to SOS Thailand, protein insect farmers (BSF) and wildlife breeding stations countrywide for further food processing or animals’ feed. Outcomes include support animal feed’s cost reduction, reduction of food waste to landfill by 3O,OOO tonnes per year.

The continuous project to raise protein insects

Lotus’s expanding cooperation with the government sector through signing a memorandum of understanding with the Bio-Based Economic Development Office (Public Organization) or BEDO within the Ministry of Natural Resources and Environment, to increase knowledge transfer in the protein insect breeding project. This economic insect is capable of substituting ready-made animal feed thus reducing animal feed expenses among farmers. The unsold food donated to farmer networks from branches to raise protein insects takes place in 1O provinces including Udon Thani, Roi Et, Maha Sarakham, Sisaket, Ayutthaya, Pathum Thani, Kanchanaburi, Chanthaburi, Surat Thani and Phetchabun. With over 4OO participating Lotus’s supermarkets, hypermarkets and mini supermarkets participating. In 2O23, deliver over 495 tonnes per year of unsold food.

“Zero Food Waste to Landfill (processed into animal feed)” project

Makro and Lotus’s signed a memorandum of understanding on food collaboration for wildlife, joining hands with the Department of National Parks, Wildlife and Plant Conservation to transfer unsold vegetables, fruits or processed meat and bakery products which are suitability for consumption to 17 animal rescue centers and zoos under the National Park Service supervision. In order to maintain maximum resource utility, reduce waste quantities, and assist in reducing wildlife food and welfare budgets, a total of 1,428.32 tonnes of food was delivered to animal rescue centers and zoos in 2O23

Measures for reuse production

Creating Value Added for Process By-Products continuation project

CPRAM Company Limited (Lat Krabang) highlights waste management at source and reduction of in-process loss, in addition to creating value added for surplus ingredients. The surplus can be developed into new products, helps reduce food waste. One instance of adding value and developing new products from raw material surplus, a method to reduce food wastage, is the development of garlic bread products and blueberry cheese pie, etc.

Impacts and Benefits

Reduction in food loss from the production process

Manage food waste

Added value to products through sales

Recycling Measures per Circular Economy Framework

ZERO Waste to Landfill project

CPRAM carries out various projects to manage waste and leftover materials utilizing the 3Rs (Reduce, Reuse, Recycle) waste system in an integrated manner. The project implementation yields 1OO% waste management, which can be categorized as follows:

Impacts and Benefits

Waste elimination without the landfill process

Generate income from waste and excess materials on average

| Waste type | Total quantity | Total quantity |

|---|---|---|

Breadcrumbs Breadcrumbs |

Animal Feed Animal Feed |

|

Food loss Food loss |

Animal Feed Animal Feed |

|

Sludge from wastewater treatment Sludge from wastewater treatment |

Biofertilizers and soil conditioners Biofertilizers and soil conditioners |

|

Plastic waste Plastic waste |

Plastic pellets Plastic pellets |

|

Glass and plastic bottle waste Glass and plastic bottle waste |

Recycled Recycled |

|

Hazardous waste Hazardous waste |

Used as a raw material in cement factories Used as a raw material in cement factories |

|

General waste General waste |

Fuel RDF in power plants Fuel RDF in power plants |

“Transform Waste to Benefits (Bio Fermented Solution)” continuation project

Makro has collected food waste, vegetables, and fruits no longer suitable for sales and consumption to convert into bio-fermented solution (EM). The solution helps remove grease stains in distribution centers for the fourth consecutive year. In 2O23, approximately 1 million liters of biologically fermented solution or EM solution was produced from 15O branches nationwide for distribution among store operators or interested agencies for water treatment and cleaning purposes in additional to supporting the “Bangkok is a livable city” project. A total of 33 distribution centers delivers biologically fermentation solution produced from food waste were distributed to 2O District Offices in Bangkok for canal wastewater treatment, tree enrichment solution, or insect repellents.

Impacts and Benefits

Reduced food waste through conversion into bio-fermented water (EM) for BMA

Waste audits to identify opportunities for improving waste performance

CP ALL continuously collects, monitors, reviews, and analyzes data on waste all operational areas, including manufacturing facilities, distribution centers, 7-Eleven stores, Makro and Lotus sales centers, and offices. Assessments are conducted quarterly using three primary methods: 1) For manufacturing, and distribution facilities, waste performance are conducted according to ISO 14001:2015 standards. In 2023, CP Ram's facilities in Ladlumkaew, Boen, Ladkrabang, Chonburi, Surat Thani, Khon Kaen, and Lamphun were ISO 14001:2015 certified. 2) For facilities located in industrial estates, waste management ,wastewater treatment are assessed by the Industrial Estate Authority of Thailand (IEAT) or independent third-party auditors according to international standards such as ISO 14001:2015, industry-specific standards, and estate-specific standards. 3) For sales centers and offices not located in industrial estates, our central greenhouse gas management unit assesses waste management practices to identify opportunities for improvement and reduce impacts on food waste and ecosystems.

The Company measures and analyzes food waste composition from business activities and has categorized data into 7 groups.

Plants, vegetables and fruits

Meat and seafood

Dairy products

Ready-to-eat food

Beverage

Processed food

Bakery products

In 2023, the Company generated a total food waste volume of 66,710.99 tonnes, by which the Group of plants, vegetables and fruits food waste category accounted for the highest volume at 22,504.43 tonnes, representing 33.73% of total food waste volume in 2023 (the proportion of food waste by group is presented in the Performance Summary 2023).

Collaboration with the community and partners for garbage and waste management

Waste Sorting Bin or Ton Kla Rai Tang continuation project

CP ALL Public Company Limited in conjunction with schools under the Foundation for Education Future (CONNEXT ED) supported by the Company have continued the Ton Kla Rai Tang project for the 4th consecutive year. The project focuses on sustainable waste management for an improved environment through instilling a socially responsible conscience in youth through participating in waste separation from the source in the smallest community unit. By way of Ton Kla Rai Tang, “No bins” are required or minimal waste is generated because of biodegradable material separation and recyclable materials removal from general waste until only non-utilizable material is left and is thus declared garbage. The fostered partnerships with merchants and school vendors to cease sales of items eventually forming wastes inclusive of straws, plates, paper, single-use glasses, etc., and the development and integration of curriculum relevant to waste management. In 2O23, the Company organized the Ton Kla Rai Tang project expansion into the fourth year whereby over 595 schools within the BMA, 6O communities, 89 operators, and 2 offices, totaling 749 locations have participated. Plans for 2O24 include network expansion to 2,O92 locations nationwide.

Impacts and Benefits

Separated of waste for processing

Reduced greenhouse gas emission

Equivalence to planting

Electronic receipts/full tax invoice continuation project

The company has opened a channel for receiving receipts. Brief tax invoice and full tax invoice in electronic format Through the 7-Eleven application

Impacts and Benefits

Receipts and abbreviated tax invoices reduced

Full tax invoices reduced

Reduced greenhouse gas emissions

Equivalence to planting

e-Waste Disposal at the Right Place, Good for Heart, at Lotus’s continuation project

Lotus’s collaborates with True Corporation to expand electronic waste collection points at 2O Lotus's branches in Bangkok and surrounding areas in an effort to facilitate appropriate electronics waste separation among community members. For instance, recycling one unused mobile phone could assist in carbon dioxide emissions reduction by up to 12.6 kilograms, equivalent to cutting down of 5 large trees, when collected for recycling according to international standard waste management.

MeStyle Young Graphic Designer Contest Project Season 2

Lotus’s, in collaboration with the Office of Creative Economy Promotion (Public Organization) and Textile Industry Development Institute, provides opportunities for higher education level students nationwide to participate in designing T-shirt graphics for the Lotus’s brand within the design scope of Thai identity with style and reflecting Thai identity of the 5 regions. The collaboration supports design skills through real work experience and promotes soft power through presentations from the perspective of a new generation of graphic designers. The manufacturing process relies on recycled materials from cotton, fabric scraps, and plastic bottles, within a factory which satisfies both export and environmental standards. The fabric dye is controlled in terms of harmful chemicals and sulfur-free dyeing agents.

Impacts and Benefits

A total students submitted their work

A total recycled materials usage for shirt production

Reduced greenhouse gas emissions

Equivalence to planting

Raising Awareness Raising and Campaign for Consumption Behavioral Change

Food Waste Awareness continuation project

CPRAM Co., Ltd. has implemented projects to raise food waste awareness through the Facebook page "Thai Society without Food Waste" and created the group "Finish your plate, No food waste" as a channel to promote food waste management and reduction knowledge. Currently, over 28,813 persons have followed the Facebook page while the group has attracted 1,179 members.

In 2023, CPRAM FOOD STATION embarked on a mission to raise awareness and promote sustainable food practices among employees and the general public. The initiative focused on two key areas:

Color Waste Separation Bags, Encourage Participation, Drive for Sustainable Environment

Lotus’s develops branding, recyclable product packaging, including Grade A Lotus’s brand garbage bags which not only uphold quality standards and safety, but is available at competitive prices. The bags are available in different color coding per Bangkok's waste separation principle, namely yellow bags for recyclable waste, blue for general waste and green bags for organic waste or food waste. The mentioned approach facilitates ease in separating household wastes in preparation for effective collection management. Waste collection points are also available for respective waste collection and transfer to relevant agencies for recycling. This serves as an approach to further generate value and provide societal benefits.

Metric used to determine the compensation of executive members

The company cascaded the corporate KPIs to designated functions. A few KPIs are joint KPI for the performances that required cross-functional collaboration for food product leftover and cut-down food waste from stores. The executives including Vice President of Operation who takes part of store ordering, General Manager of Merchandise division who in charge of the customers' needs, and Senior General Manager of store operation development division who analyzes the store ordering. To achieve this target, it reflects in their 10%, 10%, and 3% weight in the respective executives’ performance evaluation (KPIs).

Waste reduction training provided to employees

CP ALL emphasizes on raising awareness and providing knowledge to employees on waste management and reduction throughout all work processes, from upstream to downstream. This includes production processes, storage, transportation, distribution, and sales to maintain product quality, safety, and consistency. This will help reduce waste in the company's operations through training, knowledge sharing, and promotional activities as follows:

Sustainability Performance Data 2O23 : Environment

Waste Disposal

| Unit | FY 2020 | FY 2021 | FY 2022 | FY 2023 | Target for FY 2023 | |

|---|---|---|---|---|---|---|

| Total waste recycled/ reused | Metric tonnes | 123,944.17 | 157,037.00 | 150,507.61 | 98,383.98 | |

| Total waste disposed | Metric tonnes | 58,498.02 | 62,372.70 | 57,194.06 | 55,755.55 | 59,000 |

| - Waste landfilled | Metric tonnes | 56,746.45 | 60,305.62 | 54,456.37 | 53,027.21 | |

| - Waste incinerated with energy recovery | Metric tonnes | 1,744.28 | 1,986.78 | 2,686.53 | 2,688.26 | |

| - Waste incinerated without energy recovery | Metric tonnes | 7.29 | 80.30 | 51.16 | 40.08 | |

| - Waste otherwise disposed | Metric tonnes | 0 | 0 | 0 | 0 | |

| - Waste with unknown disposal method | Metric tonnes | 0 | 0 | 0 | 0 | |

| Data coverage (as % of denominator) |

percentage of: Revenue | 95.46 | 95.52 | 100 | 100 |

Other Information

Performance Data of Sustainable Waste Management

| GRI Starndard | Required Data | Unit | 2019 | 2020 | 2021 | 2022 |

|---|---|---|---|---|---|---|

| 306-3 (a) 2020 | Total waste generated | Tonnes | 174,461.64 | 182,442.19 | 219,409.69 | 207,701.67 |

| 306-4 (a) 2020 | Total waste diverted from disposal | Tonnes | 126,259.35 | 125,688.45 | 159,023.78 | 153,194.14 |

| 306-4 (b) 2020 | Hazardous waste | Tonnes | 18.35 | 59.40 | 48.26 | 205.18 |

| - Recycling | Tonnes | 17.89 | 45.83 | 24.81 | 186.31 | |

| - Energy recovery (used for mixed fuel) | Tonnes | 0.46 | 13.57 | 23.45 | 18.86 | |

| 306-4 (c) 2020 | Non-hazardous waste | Tonnes | 126,241.00 | 125,629.04 | 158,975.52 | 152,988.97 |

| - Reused | Tonnes | N/A | 90.28 | 82.33 | 367.64 | |

| - Recycling | Tonnes | 119,780.06 | 117,194.78 | 149,385.17 | 139,798.98 | |

| - Composting | Tonnes | 6,460.94 | 6,613.28 | 7,254.84 | 10,058.43 | |

| - Energy recovery (used for mixed fuel) | Tonnes | N/A | 1,730.71 | 1,963.33 | 2,667.67 | |

| - Others (animal husbandry) | Tonnes | 0 | 0 | 289.86 | 96.25 | |

| 306-5 (a) 2020 | Total waste directed to disposa | Tonnes | 48,202.29 | 56,753.74 | 60,385.91 | 54,507.52 |

| 306-5 (b) 2020 | Hazardous wast | Tonnes | 25.84 | 12.74 | 83.28 | 214.04 |

| - Incineration | Tonnes | 20.20 | 7.29 | 74.89 | 14.25 | |

| - Landfill | Tonnes | 5.64 | 5.45 | 8.39 | 199.80 | |

| 306-5 (c) 2020 | Non-hazardous waste | Tonnes | 48,176.45 | 56,741.00 | 60,302.64 | 54,293.48 |

| - Incineration | Tonnes | 1,778.93 | 0 | 5.41 | 36.91 | |

| - Landfill | Tonnes | 46,397.52 | 56,741.00 | 60,297.23 | 54,256.57 | |

| Percentage of total waste diverted from disposal per total waste generated | Percentage | 72 | 68.89 | 72.47 | 73.75 | |

| 306-3 (c) 2020 | Total food waste | Tonnes | 58,864 | 65,347.90 | 66,983.07 | 64,410.08 |

| - Fruits and vegetables | Tonnes | N/A | 7,764 | 19,899.06 | 21,304.13 | |

| - Meats and seafood | Tonnes | N/A | 6,408 | 3,766.27 | 4,534.33 | |

| - Dairy | Tonnes | N/A | 2,381 | 2,315.32 | 3,582.20 | |

| - Ready to eat (RTE) | Tonnes | N/A | 22,106 | 18,041.47 | 16,959.04 | |

| - Beverage | Tonnes | N/A | 1,794.25 | 1,265.83 | 1,503.45 | |

| - Process food | Tonnes | N/A | 1,076.70 | 655.59 | 1,962.90 | |

| - Bakery | Tonnes | N/A | 15,235.46 | 12,593.43 | 14,252.95 | |

| - Others | Tonnes | N/A | 8,582.51 | 8,446.11 | 311.08 | |

| 306-4 (a) 2020 | Food waste utilization | Tonnes | 17,943 | 18,033.87 | 12,611.83 | 16,260.86 |

| - Delivered for further consumption (Reduce) | Tonnes | N/A | 0 | 0 | 0 | |

| - be used as animal feed (Reuse) | Tonnes | N/A | 17,476.17 | 12,014.58 | 14,926.75 | |

| - reuse making fertilizer, biogas (Recycle) | Tonnes | N/A | 59.91 | 508.76 | 1,321.16 | |

| - นused to produce energy (Energy Recovery) | Tonnes | N/A | 497.80 | 88.49 | 12.94 | |

| 306-5 (a) 2020 | Total food waste directed to disposal | Tonnes | 40,921 | 47,314.02 | 54,371.24 | 48,149.21 |

| - Landfill | Tonnes | N/A | 47,314.02 | 54,371.24 | 48,149.21 | |

| Food waste prevention | Tonnes | N/A | N/A | 21,314.71 | 31,230.11 | |

| - Order optimization | Tonnes | N/A | N/A | 5,079.31 | 7,293.17 | |

| - Material for new product | Tonnes | N/A | N/A | 1,969.00 | 9,848.36 | |

| - Animal feed | Tonnes | N/A | N/A | 14,225.00 | 13,740.13 | |

| - continue consumption (Reduce) | Tonnes | 0 | 0 | 41.40 | 348.45 |

Breakdown food waste data set was sub-set of and included in total waste generated which is presenting above

Related Policy and Guideline

| Food Loss and Waste Management Policy | Download |