Sustainable Packaging Management

Key Performance in 2023

Reduce virgin plastic usage in packaging production from food packaging research and development projects

1.84% (993.77 tonnes)Plastic packaging from recycled material

ร้อยละ 4.48% (2416.60 ตัน)Reduce greenhouse gas emissions from plastic usage reduction, totalling

390668.57 tCO2eRecycling Rate

0.16% (88.82 ตัน)Recycled Post-consumer Packaging

6.17% (3327.82 ตัน)Key Progress in 2023

Research programs to design and develop Eco-Design packaging for Private Brand products through collaboration with suppliers

Program to eliminate usage of poor recyclability packaging materials and packaging

Single Use Plastic reduction program

Post-consumer packaging recall program

Post-consumer packaging reuse program

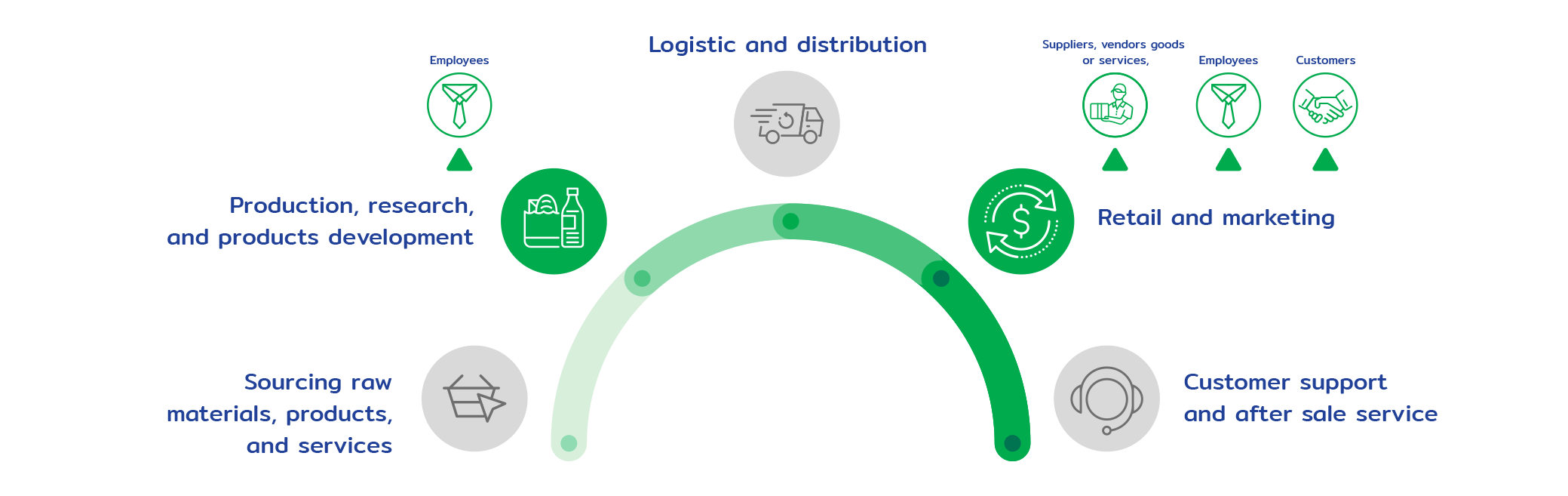

Significantly Affected Key Stakeholders

Supporting the SDGs

SDG 8 Promote sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all

8.4 Improve progressively global resource efficiency in consumption and production and endeavour to decouple economic growth from environmental degradation

SDG 12 Ensure sustainable consumption and production patterns

12.2 Achieve the sustainable management and efficient use of natural resources

12.5 Substantially reduce waste generation through prevention, reduction, recycling and reuse

Performance Against Goal

2030 Goal

100%Private Brand utilizing plastic packaging

must be reusable, recyclable, or compostable by 2O25 for operations in Thailand and by 2O3O for overseas operations

Progress against goals

Performance Summary 2023

Reduction of virgin plastic usage in packaging

Reduction of virgin plastic usage in packaging

Reduction of single-use plastics usage

Post-Consumer Packaging recycled

Reclaimed Packaging

Plastic water bottles

Cardboard box

The use of environmentally friendly plastic packaging

Use of reusable packaging

Remark : (% Coverage 100)

Use of recyclable packaging

Remark : (% Coverage 100)

Use of recycled material/recycled content

Remark : (% Coverage 100)

Use of compostable packaging

Remark : (% Coverage 100)

Packaging usage

Total plastic packaging consumption

Remark : (% Coverage 100)

Average plastic packaging consumption per store

Share of total plastic consumption classified by type

Non-plastic packaging usage type

| Type | Coverage (% of cost of goods sold) | Weight of packaging Consumption (tonnes) | Recycled or certified Material packaging (%) | 2O23 Goal (%) |

|---|---|---|---|---|

Wood or Paper Wood or Paper |

100 |

6816.72 |

65 |

65 |

Metal (Steel, Aluminum) Metal (Steel, Aluminum) |

100 |

7.50 |

100 |

100 |

Glass Glass |

100 |

227.36 |

100 |

100 |

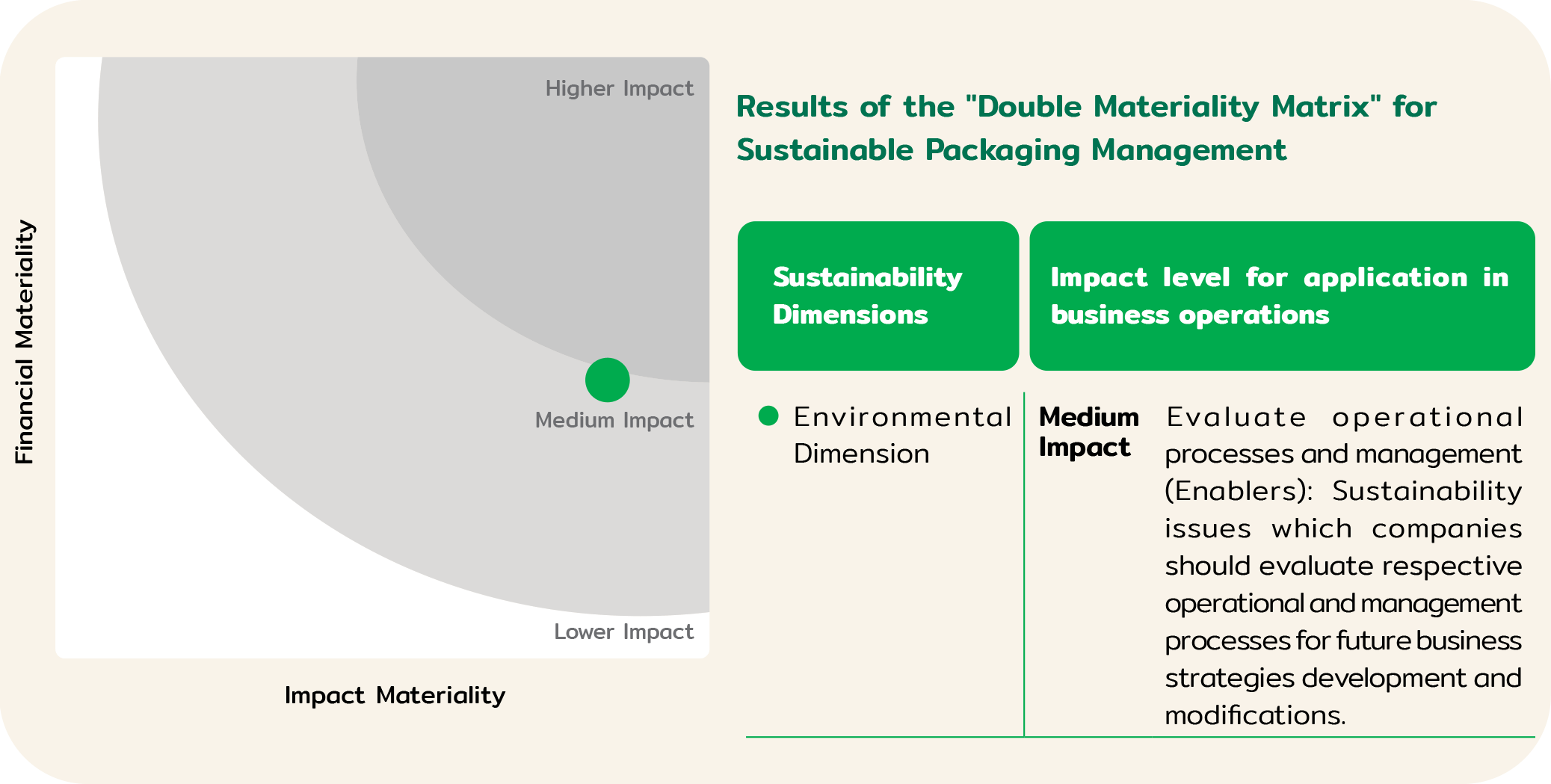

Risks and Opportunities

Product overpackaging to maintain product quality, prevent product damage while in transit, market promotions, or to increase distribution convenience all contribute to enormous waste quantities. Current products purchased through online channels and transported especially exacerbate the sheer volume of waste. Studies have shown that discarded plastic waste remains in the environment thus causing land,

water and air pollution leading to ecosystem imbalance and impact towards human health. Consequently, consumers take into account sustainable packaging as a criterion when deciding to purchase or support a product. This critical issue poses challenges to all global industrial groups, especially retail and wholesale businesses, thus requiring research and development departments in companies to develop innovative and alternative materials. From design to production and efficient supply chain management, business activities can be implemented harmoniously throughout the value chain while ensuring that alternative packaging solutions will not trigger additional problem. For instance, the introduction of recyclable but heavy alternative packaging results in increased greenhouse gas emissions in relation to transportation or alternative lightweight packaging which reduces resource utilization and costs but poses recycling difficulties.

The continuous development of environmentally friendly packaging in conjunction with suppliers, etc., under confines of appropriate cost management aims to create safe packaging which maintains product quality while posing zero health risk to employees within the manufacturing process and customers in direct or close contact with the packaging.

Therefore, innovative management and appropriate plastic packaging management processes are important driving forces in increasing product distribution capabilities and for wider product acceptance in the world market.

Management Approach

The Company abides by laws, regulations and requirements related to packaging waste management, inclusive of prohibiting usage of product packaging and transportation wraps which may affect business operations. In addition, the Company emphasizes developing technology and innovation for complete packaging management in preparation for challenges and takes upon the role of organization leader in establishing sustainable packaging policies. Operational guidelines cover packaging design and selection for the Company controlled products (Private Brand) which maintain environmentally friendly properties, for instance Reusable Packaging, Recyclable Packaging, Compostable Material Packaging and Recycled Material Packaging, including packaging materials certified by reliable sources, etc.

The Company places importance regarding data collection process, performance appraisals, and database central data analysis, as a means for policies review and establishing future operational plans. This approach ensures efficient Company packaging management, appropriate operations process, minimization of packaging waste generation, reduced environmental and health impact towards all stakeholders, in addition to satisfying green market consumers both nationally and internationally.

Circular Economy

The Company manages waste according to Circular Economy concepts which endeavors to minimize plastic and packaging waste destined for landfills. This approach enables plastic packaging for Private Brand products to be reusable, recyclable, and compostable under the "Reduce-Reuse-Recycle (3R)" concept by operating under 3 main measures as follows:

Reduce plastic usage

at-source

--------

Announcement of “Sustainable packaging” policies set the directional framework in terms of operations. strategy, plans and indicators, promotes sustainable packaging innovations research and development, investigates new packaging options, and promotes environmentally friendly packaging

Reduce and replace plastic usage at consumption stage

--------

Initiated strategic projects to reduce single-use plastics consumption and stimulate participation among customers,

society, and communities

Reduction of packaging waste after consumption

--------

Initiated a packaging strategy project according to Circular Economy principles through cooperation with relevant sectors. The initiative entails disclosing information regarding the amount and type of plastic used, consumption reduction, recycling, reusing, and plastic eliminating through regular sustainability reports every year

The Company systematically operates according to sustainable packaging management measures whereby operational performance is monitored and recorded regularly. The results and benefits received from the project implementation, inclusive of single-use plastic packaging reduction, packaging waste reduction by category, reduction in greenhouse gas emissions, etc., through various project implementation in 2O23 are as follows:

1. Reduce plastic usage at-source

Design, research and develop Eco-Design packaging which reduces virgin plastic quantities in accordance with Circular Economy principes in Private Brand products.

Plastic thickness reduction continuation project

Collaborate with partners to design packaging with appropriate thickness.

Golden banana bag

CP ALL plastic thickness reduction from

30 microns to 25 microns, totaling 29.85 tonnes

2 partition tray, 7-Fresh Frozen products

CP ALL developed plastic pellets and reduced plastic thickness from 0.92 millimeters to

0.82 millimeters, totaling 34.07 tonnes

Filling and value filled salad tray

CP ALL plastic thickness reduction from

0.5 millimeters to 0.4 millimeters, totaling

77.40 tonnes

Food tray (Food place)

CP ALL plastic thickness reduction from

0.6 millimeters to 0.5 millimeters, totaling

16.54 tonnes

Stickers for frozen products

CP ALL frozen products stickers thickness reduction for from 90 microns to 80 microns, totaling 5.39 tonnes

Heated product film roll

CPRAM plastic thickness reduction from

60 microns to 40 microns

Impacts and Benefits

Virgin plastic usage reduction

Reduced GHG emission

Equivalent to the plantation

Cancel or replace sticker usage continuation project

Chilled Thai Food*

CPRAM develops laminate film innovation, sealing film material capable of being printed, to replace sticker usage

*Products including rice with minced pork, rice with Kra Pho and Fried Egg, Pork Panang Omelette Rice, Crab Fried Rice, Stir-Fried Noodles with Pork

Steamed rice bowl

CP All develops steamed rice bowls with side prints to replace sticker usage, totaling 33.73 tonnes

Impacts and Benefits

Reduced plastic usage

Reduced amount of waste from sticker usage

Reduced GHG emission

Equivalent to the plantation

Collaboration with suppliers to modify packaging formats and production methods continuation project

Half portion box, 1 partition tray

CP ALL uses film to cover tray lids (Top Seal) instead of plastic lids with top side stickers, reducing plastic usage by a total of 93.88 tonnes

2 partition tray, Top Seal

CP ALL has redesigned the tray lid using film (Top Seal) instead of the plastic lid with a top side sticker, reducing plastic usage by 5.78 grams per piece, totaling 21.85 tonnes

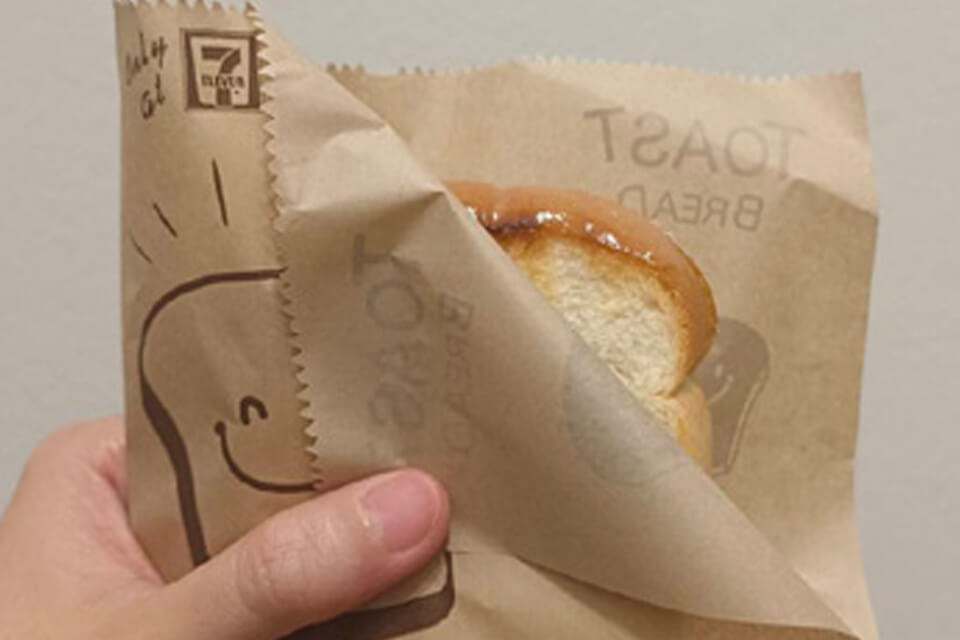

Toast paper envelope

CP ALL reduces the use of PE coated paper to Grease proof paper.Reduced plastic use by

11.61 tonnes

21 ounce rice bowl

CP ALL modified the plastic formula in packaging production, reducing plastic usage by 2.70 grams per piece, totaling 25.99 tonnes

Cold dessert cup

CP ALL modified designs to reduce plastic weight by 0.70 grams per piece, totaling 2.24 tonnes

Ice glass 22 oz

CP ALL modified the production process from Injection to Thermoform and changed the material from PP to PET, reducing plastic usage by

7.50 grams per piece, totaling 107.30 tonnes

New design short spoon

CP ALL modified product design, reducing plastic weight by 0.28 grams per piece, totaling

57.41 tonnes

Plastic tray

CPRAM developed kraft paper packaging which is free of chemicals or contaminants with high security and food safety properties as a replacement to plastic trays, reducing plastic usage by 7.09 grams per piece

Thermoformed meat tray

Lotus’s designed packaging which requires less plastic and utilizes recycling conducive materials, reducing plastic usage by over 400 tonnes per year

Impacts and Benefits

Virgin plastic usage reduction

Reduced GHG emission

Equivalent to the plantation

Paper reduction continuation project

Paper cup

CP ALL reduced the gram of cold drink paper in the Non All Café product group, including Gulp drinks, Slurpee and pressed Jet Spray, totaling

132.63 tonnes

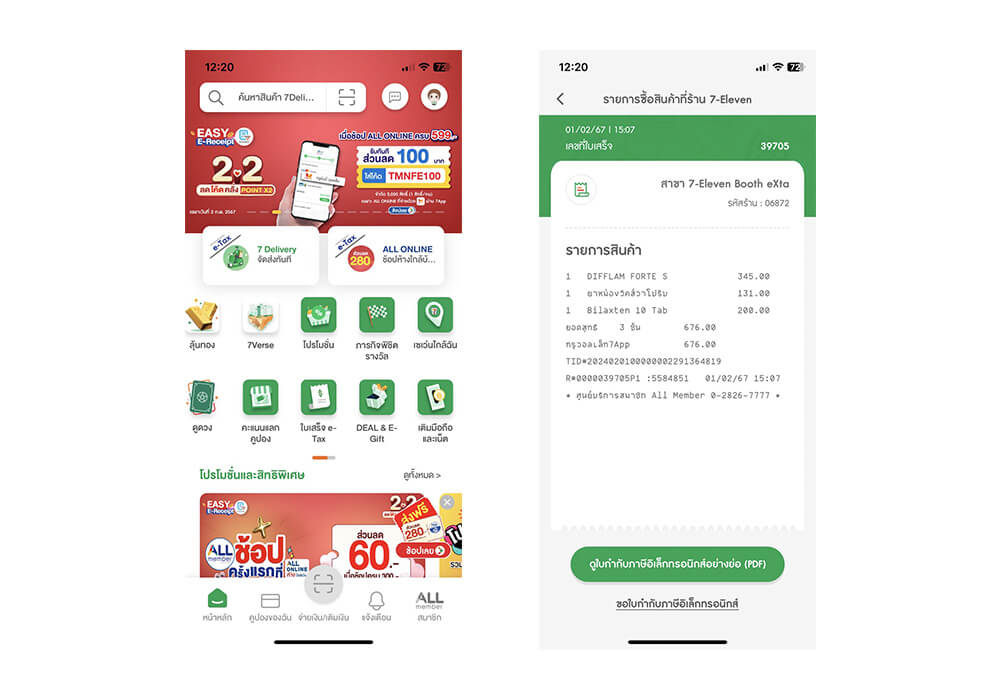

Product receipt

CPALL replaced paper receipts with electronic slips

Hot sandwich box

CP ALL replaced Artcard pape r with Greasep roof paper, totaling 763.40 tonnes

Impacts and Benefits

Reduced paper usage

Reduced GHG emission

Equivalent to the plantation

Packaging materials selection from sustainably managed sources continuation project

Toast paper envelope

CP ALL uses Greaseproof paper certified by the Program for the Endorsement of Forest Certification Scheme (PEFC), totaling 58.07 tonnes

Hot sandwich bags

CP ALL uses Greaseproof paper certified by the Program for the Endorsement of Forest Certification Scheme (PEFC), totaling

347.62 tonnes

Paper wrapped straw

CP ALL uses paper certified by the Forest Stewardship Council (FSC) organization, totaling 326.51 tonnes

7-Eleven store receipt paper

CP ALL sources paper from replanted forests which have been inspected and certified by the Forest Stewardship Council (FSC) organization

Sticker base paper

CPRAM sources paper from replanted forests which have been inspected and certified by the Forest Stewardship Council (FSC) organization

Impacts and Benefits

Uses of sustainably sourced paper

Reduced GHG emission

Equivalent to the plantation

Reusable packaging selection continuation project

T. Durable bag

CP ALL designed for durability and reusability

Corrugated boxes used in factories

CPRAM corrugated boxes used for reuse in factories

Resurrection bag

Lotus’s designed plastic bags capable of multiple reuse cycles

Impacts and Benefits

Reduced plastic usage

Reduced paper usage

Reduced GHG emission

Equivalent to the plantation

Compostable packaging continuation project

World conserving glass

CP ALL selects Polybutylene Succinate (PBS) coated paper for hot and cold drinks in 7-Eleven stores on islands, educational institutions and offices for 1,200 branches, totaling 303.43 tonnes

Wooden chopsticks

CP ALL selects biodegradable wooden chopsticks, totaling 12.47 tonnes

Coffee stirrer

Replace plastic coffee stirrers with biodegradable wooden coffee stirrers, totaling 1.48 tonnes

Meatball skewers

CP ALL selects biodegradable meatball skewers, totaling 330.37 tonnes

Impacts and Benefits

Uses of biodegradable materials

Reduced GHG emissio

Equivalent to the plantation

Recycled Material packaging continuation project

Carrying bags used in 7-Eleven stores

Contains 30% recycled materials

Garbage bags used in offices and distribution centers

Contains 100% recycled materials

Water pallets in 7-Eleven stores

Contains 100% recycled materials

CPRAM corrugated cardboard box

Contains 90-100% recycled materials

Impacts and Benefits

Virgin plastic usage reduction

Reduced GHG emission

Equivalent to the plantation

Elimination of packaging materials posing recycling challenges for Lotus’s brand products project

Lotus’s has established a goal to eliminate difficult-to-recycle materials from all Lotus’s brand products by 2030 as a measure to assist in environmental impact reduction. In 2023, Lotus's can reduce the use of packaging made from new plastic pellets by 35.7 tonnes. In addition, Lotus’s also recognizes the importance of supporting consumer behavior in waste sorting as a means to complete the Closed-Loop Packaging System and fulfill the package waste management scope. Other notable support measures include aims to raise recycling awareness and understanding among the communities while promoting recycling through packaging waste pick-up point expansion at various branches nationwide.

2. Reduce and replace plastic usage at consumption stage

The Company promotes behavior change among consumers and employees with the concept of “reduce receiving, reduce giving = reduce use”.

“Reduce and replace” single-use plastic” project

The Company invites 7-Eleven store patrons to refuse to accept plastic spoons, forks, straws, glasses, and to carry their own cloth carry bags to reduce plastic packaging usage and continuously campaign for usage of alternative, environmentally friendly materials. In 2023, There are 3,882 million pieces plastic reductions and single-use plastics: spoons, forks, tubes and glass. 1,282 million tickets.

Addi tiona l ly, the Company r un s the campaign "Just Refuse = Plant Trees" to support reducing single-use plastic. When customers refuse plastic bags, spoons, forks, and straws when purchasing food and beverages from 7-Eleven stores, they can exchange that for a water droplet to water trees in the 7APP. When customers accumulate enough droplets to reach the "yield" level, they can send real trees to the "Planting Forests, Planting Futures" project to increase green areas in Thailand. In 2023, customers were able to accumulate droplets from reducing plastic use and donate trees to the "Planting Forests, Planting Futures" project in a total of 843,983 trees.

Impacts and Benefits

Reduced single used plastic usage

Reduced GHG emission

Equivalent to the plantation

Green packaging continuation project

7-Eleven stores campaign to refrain from handing out small bags except for hot items and switch to environmentally friendly packaging in a stores located on islands or near natural attractions, numbering over 1,200 stores.

Green Coffee Shop continuation project

Coffee shops and bakery houses within the CP ALL Public Company Limited group continued to reduce solid waste including plastic cups and single-use plastic straws as jointly announced to the Ministry of Natural Resources and Environment. The company continuously cooperates with entrepreneurs to reduce plastic waste to encourage coffee shops to separate waste within their stores for recycling purposes or reuse. In addition to reducing waste quantities, the usage of creative packaging or environmentally friendly materials through various activities of the 3 brands are as follows:

ALL Cafe

----------

Kudsan Bakery & Coffee

----------

Bellinee's Bake & Brew

----------

Say Hi to Bio Say No to Foam Project

Makro collaborates with suppliers to produce and develop biodegradable packaging made from natural materials as a replacement to foam and plastic which harms the environment. The Bio Base products used, which are sourced from natural plant pulp including bagasse, bamboo pulp, pure wood pulp, etc., are safe, non-toxic, not harmful to health, completely biodegradable, and are formed into over 40 items including plates, bowls, cups, glasses, boxes, etc. The goal to stop sales of single-use foam packaging in all distribution centers nationwide has given rise to the center’s recognition in biodegradable packaging adoption at the national level. The result of this approach incentivizes restaurant operators and general customers to implement biodegradable packaging solutions. Over 530 eco-friendly packaging options are currently available.

Impacts and Benefits

Environmentally friendly packaging sales increased

All branches halted foam packaging sales

Environmentally friendly packaging products potentially reduce single-use foam food packaging waste by up

3. Reduction of packaging waste after consumption

The Company establishes cooperation with suppliers, public sectors, private sectors, and educational sectors to separate waste, collect plastic packaging for recycling (Recycling Rate), and recycled (Recycled Post-consumer Packaging).

Plastic packaging collection for recycling program

Recycling station and resurrection bag continuation project

Lotus’s continues to campaign and support consumers in achieving maximum utility of available resources, introduce behaviors in separating waste to enable recycling processes, establish comprehensive waste management systems through taking advantage of different branches to increase community coverage. The various branches act as Recycling Stations and create channels for receiving raw materials and transferring to network partner systems for recycling or reuse.

Impacts and Benefits

Collected almost and aluminum cans

stretched plastic

boxes and cardboard boxes

In addition, Lotus’s has strictly discontinued providing single-use plastic bags in accordance with government policy since 2020 and has developed a "Resurrection Bag", a plastic bag that can be reused many times, made from recycled materials. This bag is sold to customers requiring it and can be exchanged for a new one free of charge if the old one is damaged. All damaged Resurrection Bags will be recycled into new Resurrection Bags as an approach to reduce plastic usage.

Impacts and Benefits

Reduce plastic usage from Resurrection Bags Project

Reduced GHG emission

Equivalent to the plantation

“Waste Sorting Bin” project

The Company campaigns for Thai people to assist in plastic waste separation which facilitates the “waste sorting bin” Circular Economy concept management system. In 2023, the mentioned bins are installed in front of front of 7-Eleven stores nationwide.

Postconsumer packaging reuse program

Eleven stores handle bag" from pallet wrapping film in distribution centers continuation project

CP ALL Public Company Limited in collaboration with suppliers has collected plastic waste from the pallet wrapping film in distribution centers across the country for recycling and conversion into handle bags for use in 7-Eleven stores. The produced handle bags are 37 microns thick and therefore is durable and reusable.

Impacts and Benefits

Reduced plastic waste to landfill

Reduced GHG emission

Equivalent to the plantation

7-Eleven stores shopping baskets from broken brake cases at distribution centers continuation project

The Company collects damaged brake case crates from distribution centers and processes them into 7-Eleven store shopping baskets for customers as a means to reduce business activity waste and enable more cost-effective resource usage.

Impacts and Benefits

Reduced GHG emission

Equivalent to the plantation

“Employee shirts” made from plastic bottles continuation project

The Company recycles plastic bottles into uniform shirts for 7-Eleven store employees and polo shirts for employees in the distribution center and office.

In 2023, the Company produced over 728,111 shirts for employees in a process which reduced over 3,088,620 plastic bottles required for processing. The Company also expanded operations with CP Axtra Public Company Limited under the project “Makro Save the world - empty bottles not to be wasted” in recycling plastic bottles into employee shirts.

Impacts and Benefits

Reduced plastic waste to landfill

Reduced GHG emission

เทียบเท่าEquivalent to the plantationการปลูกต้นไม้ยืนต้น

24 Hour Save the Island Project Earth-saving bricks from orphaned plastic on the island

CP ALL in collaboration with school network partners within the Foundation for the Future of Education, CONNEXT ED, under the supervision of CP ALL, a Ton Kla Rai Tung Organization, and the public and private sectors extended the “Ton Kla Rai Tung” project turning plastic waste on the island into “Brick saves the world” by aiming to reduce island waste quantities by an average of 50% while generating income back to the island community through 3 principles:

In 2O23, the Company piloted the "Green Living" model to protect the island 24 hours a day on Koh Phangan in 3 municipalities: Koh Phangan Subdistrict Municipality, Phet Phangan Subdistrict Municipality, Ban Tai Subdistrict Municipality, and on Koh Tao, Surat Thani Province. Plans for expansion include operations in 11 islands in 8 provinces by 2030

Impacts and Benefits

Plastic wraps recycled

Multi-purpose and environmentally friendly sports field delivery

Support budget for forming environmentally friendly bricks

Reduced GHG emission

Equivalent to the plantation

Reduce the cost of building a sports field for schools by over

Adding value to managed contaminated plastic plant waste continuation project

CPRAM collects contaminated plastic waste from the plant production process for shipment to external processing companies and further conversion into waste fuel (Refuse Derived Fuel: RDF). The produced biofuel from waste has a high specific heat and is thus considered a clean source of energy

Impacts and Benefits

Plastic waste usage

Reduced GHG emission

“Empty Bottles, Not Empty Values” continuation project

The sorting of empty plastic bottles offers a number of benefits. CP Axtra Public Company Limited therefore collects clear plastic bottles (PET) to be processed into various products and as a measure to reduce global resource consumption, merit making, creating careers and supporting public health.

In an effort with Makro employees, PET plast bottles were accepted at the drop-off point at the head office or Makro distribution center.

Results

Collection of clear plastic water bottles

Capable of conversion into employee shirts

Equivalent to reducing greenhouse gas emissions

In collaborated with Indorama Ventures Public Company Limited, the Company recycled 600 ml PET bottles into fibers to produce high quality PPE suits (18 bottles can produce 1 PPE suit) in addition to supporting the production of sports shirts from the plastic fibers. The sports shirts are donated to children living in communities around the branch. Makro distribution centers which double as a plastic bottle drop-off point include 5 branches namely the Nakhon Pathom branch, Salaya branch, Phetkasem branch, Bang Bon branch and Charansanitwong branch.

Results

Donation of clear plastic water bottles

Equivalent to reducing greenhouse gas emission

The Company cooperates with Wat Chak Daeng, Phra Pradaeng District, Samut Prakan Province to collect used PET bottles from the distribution center near Wat Chak Daeng to be processed into monk robes. Remote stores will collect PET bottles for sale and donate money to the Chak Daeng Temple

Results

Donation of PET water bottles to Wat Chak Daeng

Financial donation to Jakdaeng temple

Equivalent to reducing greenhouse gas emissions

Example Innovative packaging research and development Project

The Company developed a new packaging for bags for hot sandwich products for hot sandwich products to reduce plastic bags usage. The project plan and timeline for all operations are divided into 4 Phases. The project is currently in Phase 4 which has been introduced for will undergo countrywide adoption. The development concept requires coverage of all 4 areas:

The product must maintain identical characteristics and quality

The customers, both internal customers (operation ) and external customers (consumer) must find the product acceptable

The environmental aspect encompasses requirements for newly developed packaging to be recyclable and materials be certified as sustainable (Sustainably Managed Renewable Resources)

The economics aspect entails control of overall product cost to ensure product sales at the same assessable-to-customers price and does not affect the Company cost-profit outlook

The experiment was carried out in order to elicit solutions to maintaining product quality, safety, and customers convenience while not affecting overall product cost. The initiated project yielded greaseproof paper envelopes suitable for customers to handle without the need to use plastic carry bags. The envelope replaces art card boxes, which use thick paper and holes to vent moisture, thus no longer requiring carry bags.

Impacts and Benefits

Product quality upon delivery is better than or equivalent the quality level using the original packaging

Capable of protecting the product from contamination arising from external conditions

Usage of paper certified to be sustainably managed, renewable, and recyclable

Does not affect the overall product

Budget for research and development in the amount

Reduce single-use plastic bags by approximately

Reduce paper usage, through modifying paper type, by approximately

Metric used to determine the compensation of executive members

The company cascaded the corporate KPIs to designated functions. A few KPIs are joint KPIs for the performances that required cross-functional collaboration. Executives, including Assistant Vice President of Purchasing division, Senior Manager of Packaging Development division - Food Support Center, and General Manager of Green Packaging Engagement and Partnership division, who are responsible for lowering amount (tons) of plastic used in products packaging. The actions require collaboration from suppliers to apply 3R concept to their production. To achieve this target, it reflects in their 10%, 25% and 30% weight in the respective executive’s performance evaluation (KPIs).

Related Policy and Guideline

| Packaging Policy | Download |